Product solutions

Company Masterplast Nonwoven is able to fulfil the complex and specific product requests of the clients coming from different market segments of the industry. Due to the long history and roots in the construction materials, the biggest experience and product portfolio we are offering to our partners of the building market. However, the biggest focus is nowadays put on the medical and hygienical products: Masterplast plays recently an active roll in fighting the pandemic by producing the raw materials of among others the protective glowns and face masks. We are also able to serve the needs of the furniture and matrass production, the agriculture and some specific needs of the automotive and filtration industry.

Construction market

Due to the long history and roots in the construction materials, the biggest experience and product portfolio we are offering to our partners of the building market. The 2 or 3 layer materials based on Linopore ensure proper water-tightness, regulable vapor permeability and massive tensile strength for the pitched roofs and the side-walls of the houses.arrow_forward

Hygienical market

Masterplast serves the requests of the hyginenical partners with specially developped PP or PE spunbonded nonwoven items which are further processed to composite materials used in the hygienical products.arrow_forward

Medical market

The usage of spunbonds and nonwoven-based one-way composite materials is getting more and more wide-spread in the healthcare and medical segment in order to meet the hygienical and sterility requirements of the 21st century. Masterplast plays recently an active roll in fighting the pandemic by producing the raw materials of among others the protective glowns and face masks. We supply our medical partners with certified and safe nonwoven materials and Linopore materials in different unit weights, colors and surface treatments in the requested roll sizes.arrow_forward

Furniture industry and mattresses

The modern furniture and matrass industry is not able to avoid the usage of the nonwoven materials, they are more cost-effective and easy to use, durable, provide enough stability, are less sensitive than the alternative products used in the past. In most cases anti-mite and antibacterial treatments ensure the safety of the end-users in the sleeping and living environment.arrow_forward

Automotive market

The PP or PE nonwovens applied in the automotive composite materials always have to meet some special needs: excellent uniformity, high tensile strength against the impacts, low melting point for the easy sealing and diverse elongation properties depending on the field of the installation.arrow_forward

Agricultural market

Agricultural nonwoven materials have to cope with the extremities of the outdoor environment, they should have high UV- and abrasion resistance, tensile strength for a longer life-cycle. These spunbonds are usually requested in different rolls widths, unit weights and colors, depending on the field of the application.arrow_forward

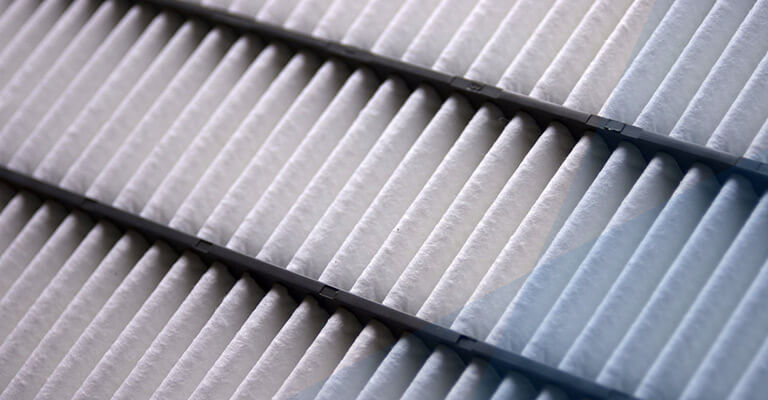

Filtration market

Industrial partners of the filtration segment use either the nonwoven materials directly on the filtration equipment at their own facility in different unit weights and roll widths or produce certified composite materials from the spunbonds either in normal or in a pleated form.arrow_forward